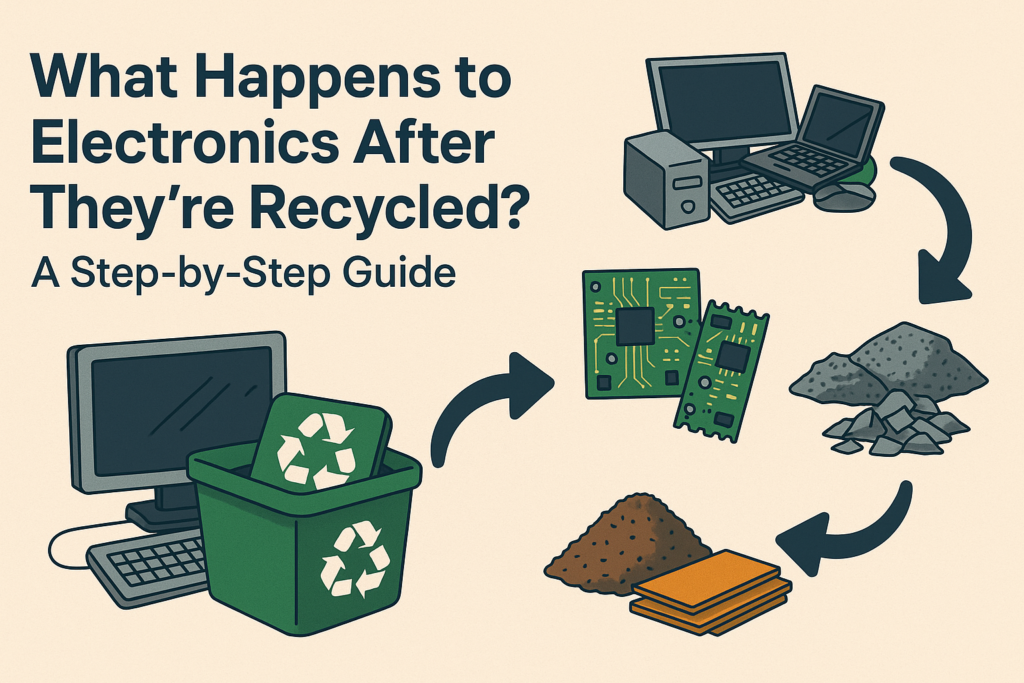

Ever wonder about the fate of your old laptop or smartphone after dropping it at a recycling center? The recycling process involves several key steps that extract valuable materials while safeguarding both data security and our environment.

The Growing Problem of Electronic Waste

EPA data shows Americans throw away over 2.9 million tons of electronics yearly, with just 20% reaching recycling facilities. The rest lands in landfills, squandering valuable resources and risking toxic contamination of soil and water.

Back in 2014, manufacturers produced more than 300 million computers and 2 billion smartphones. The rare metals used in these devices—gold, silver, palladium, copper—exist in finite supply yet can be recovered through proper recycling methods.

Electronic components often contain substances that, when improperly disposed of, leak harmful chemicals into the ground. Recycling prevents this environmental damage.

The Electronics Recycling Process

Step 1: Collection and Transportation

The journey starts when you leave your unused devices at a recycling facility. Companies like eWaste Solutions provide convenient drop-off locations and pickup services for businesses with substantial equipment volumes.

Businesses updating their technology rely on certified recyclers to handle outdated equipment and destroy sensitive data. Medical facilities, financial institutions, government agencies, and other security-conscious organizations need reliable partners to eliminate confidential information safely and efficiently.

Tracking systems using GPS-equipped vehicles and barcode identifiers establish a legal chain of custody from collection through processing. This documentation appears in your Certificate of Destruction, confirming proper handling.

Step 2: Initial Assessment and Sorting

Upon arrival, technicians evaluate each item’s condition to determine if it suits remarketing, parts recovery, or full recycling. Expert staff categorize devices by type, condition, and potential value.

Items follow different paths based on this assessment. Working equipment might head to refurbishment, while broken or obsolete devices go to materials recovery. This sorting maximizes both sustainability impact and financial returns.

Staff inspect each component using standard protocols to identify the best processing approach. This careful evaluation ensures recovery of all valuable elements while properly handling hazardous parts.

Step 3: Data Destruction and Security

Security starts with thorough data removal from all storage devices before further processing. This prevents unauthorized access to sensitive information.

Sanitization methods include software wiping that complies with NIST800-88 R1, IEEE 2883-2022, or DOD 5220.22M standards. Physical methods like degaussing and destruction provide added security. These techniques work on servers, storage systems, drives, laptops, desktops, and mobile devices.

Security-focused organizations often prefer on-site destruction services where they can watch the process before items leave their premises. This visibility builds confidence and creates records for compliance purposes.

Step 4: Asset Remarketing (When Applicable)

Many devices don’t require dismantling. Working equipment enters remarketing programs that extend technology lifecycles while generating financial returns.

Technicians clean and test equipment thoroughly, then classify it by market value. This process maximizes financial recovery for original owners through established networks of resellers, brokers and dealers.

Workers remove all identifying marks, serial numbers and barcodes before remarketing to protect previous owners’ identities. Complete tracking documentation appears in the data destruction certificate, maintaining a verifiable custody record.

Step 5: Disassembly and Separation

Technicians manually dismantle non-marketable electronics into component parts. This process demands skilled workers who understand modern device construction.

Staff separate materials for effective recycling while isolating hazardous elements for specialized processing by licensed partner facilities. This careful sorting prevents dangerous materials from contaminating recoverable resources.

The separation process targets circuit boards, plastic housings, metal frames, batteries, display screens, and wiring. Each material category requires specific recycling methods to maximize recovery rates.

Workers follow strict safety protocols during disassembly to prevent injuries and environmental risks. Specialized equipment helps staff safely break down complex devices into basic materials.

Step 6: Material Processing

Each material type undergoes specific processing to reclaim valuable resources:

- Metals: Specialized refineries extract gold, silver, platinum, and copper from circuit boards and components. These metals typically represent the most valuable recoverable materials and can reach near-original purity for manufacturing reuse.

- Plastics: Sorting machines separate plastic types before shredding and processing into manufacturing pellets. Advanced technology distinguishes between polymer varieties, enhancing recovered plastic quality and value.

- Glass: Processors handle screen glass separately, removing lead and contaminants before recycling. CRT monitors contain significant lead quantities requiring special handling to prevent environmental harm.

- Batteries: Specialized facilities process various battery chemistries—lithium-ion, nickel-cadmium, lead-acid—using type-specific methods to safely recover materials.

Step 7: Refinement and Commodity Sales

Processed materials become manufacturing commodities, completing the recycling loop. Recovered metals return to new electronics, while plastics and glass serve various industries.

This resource recovery benefits the environment by reducing mining impacts while supporting jobs, economic growth, and sustainable manufacturing. Reclaiming these materials decreases demand for new resource extraction and its associated environmental costs.

Refined materials enter global supply chains to meet manufacturing needs. This circular system exemplifies sustainability by transforming waste into resources while minimizing environmental damage and creating economic value.

The Importance of Choosing Certified Recyclers

R2 RIOS certification marks the gold standard in recycling. Certified facilities follow strict guidelines that protect against data theft and privacy breaches while upholding safety and environmental standards.

Professional recyclers adhere to compliance protocols like Gramm-Leach-Bliley and HIPAA requirements. They process all materials according to state and federal regulations and fulfill customer specifications for disposal, handling, and processing.

Accountability and transparency underpin responsible electronics recycling. Certified facilities provide detailed, audit-ready records that offer regulatory compliance documentation and peace of mind, creating valuable proof of proper handling.

Work With a Trusted Electronics Recycling Partner

At eWaste Solutions, we deliver comprehensive electronics recycling with security, compliance, and environmental protection as top priorities. Our certified methods protect your data while maximizing resource recovery from discarded devices.

Ready to recycle your electronics responsibly? Contact us today to learn about our services or schedule a pickup.

Frequently Asked Questions

How long does the electronics recycling process take?

The complete recycling process typically takes 1-2 weeks from collection to final processing, though data destruction is often completed within 24-48 hours of receipt.

Which electronics can be recycled?

Most electronic devices can be recycled, including PCs, laptops, network equipment, memory chips, LCD monitors, mobile devices, tablets, hard drives, circuit cards, keyboards, batteries/UPS, cameras, GPS devices, servers, solid state drives, computer mice, audio/video equipment, telephones and telephone systems, and many other electronic items.

Is on-site data destruction more secure than off-site?

On-site data destruction allows you to witness the process firsthand, providing peace of mind that your confidential information is protected before devices leave your premises. For organizations with strict security requirements, this added layer of verification can be valuable.

How do I know my data is completely destroyed?

Professional recyclers provide detailed, audit-ready, serialized sanitization reports for each asset. These documents account for each asset and clearly outline the entire process, creating a valuable record for maintaining audit trails and demonstrating compliance with regulatory requirements.

Can I make money from recycling my old electronics?

Some electronics recyclers offer IT asset management services that enable companies to convert retired equipment into additional revenue. Through networks of resellers, brokers, and dealers, they can help you receive reasonable compensation for items with resale value.